PRODUCT CENTER

- Product features

- Product details

-

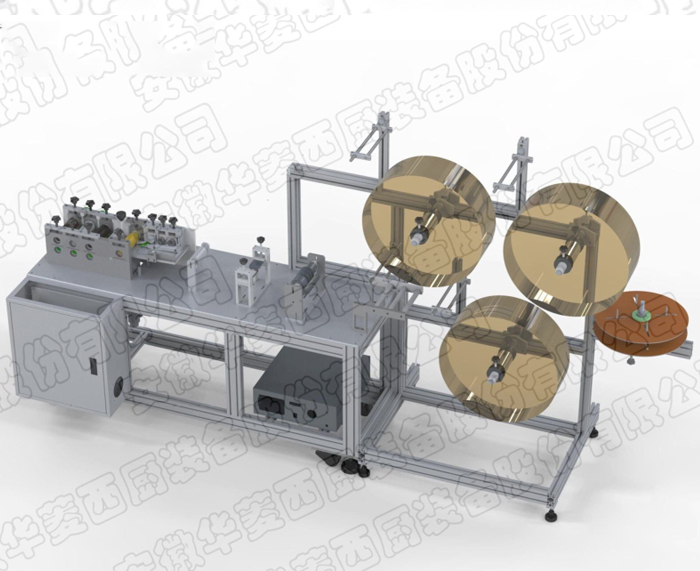

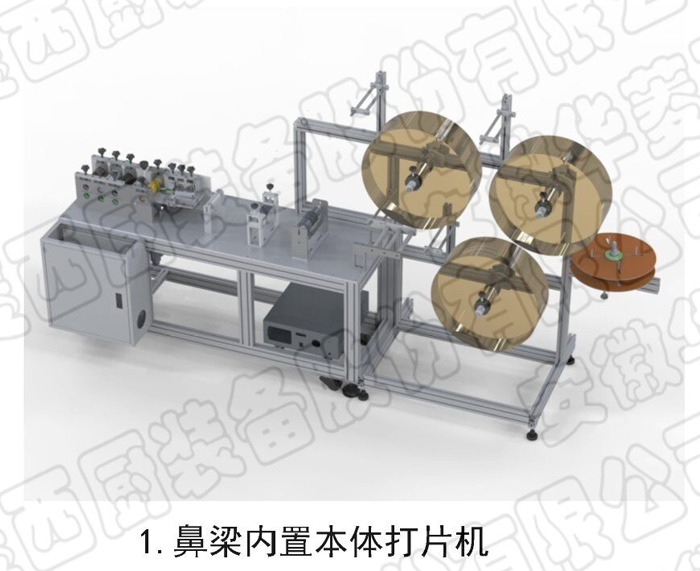

Semi-automatic N95/KN95 Mask Production Line -

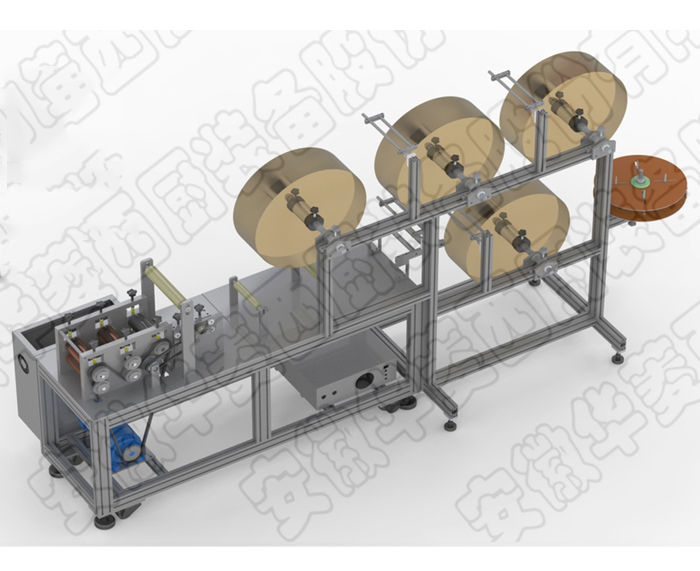

Nose bridge built-in sheet making machine

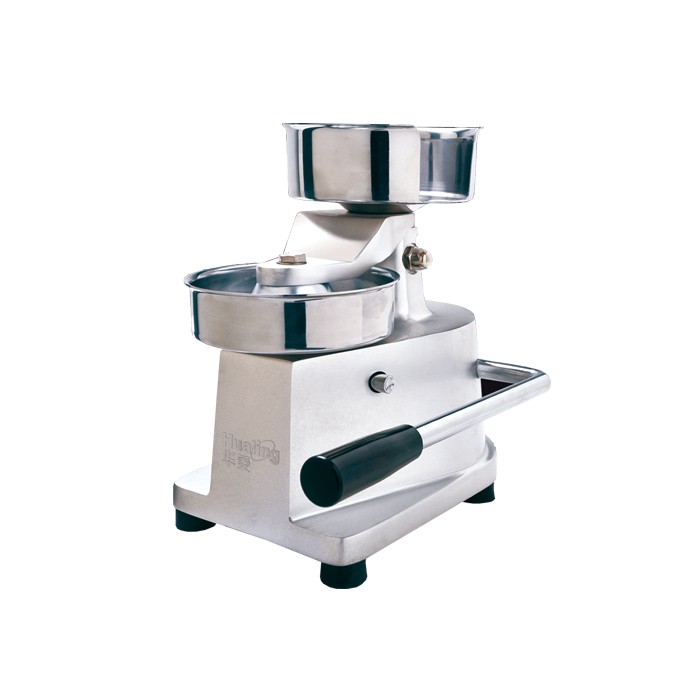

Folding edge stitching machine Ear belt welding machine

1、 Equipment introduction

The semi-automatic KN95 mask production line is made of 3 parts: nose bridge built-in sheet making machine, folding edge stitching machine and ear belt welding machine

1. Working process of the nose bridge built-in sheet making machine: install the cloth roll (4 rolls), the nose beam is automatically built under the outermost non-woven fabric, and the body is welded, cut and shaped in one time - Manual blanking.

2.Working process of the folding edge stitching machine: fold the mask in half manually, place it under the mold, step on the foot, and weld automatically.

3.Working process of the ear belt welding machine: place the mask under the mold manually,step on the foot and weld automatically.

2、Equipment features

1.The working speed of the equipment is adjustable, and the efficiency range is 50-120pcs / min.

2.Different models of masks can be produced by changing the mold.

3. Chain wheel drive, stable and reliable transmission ratio, high stability when using European standard profile finishing machine body.

4. Compact and solid structure, convenient assembly and debugging, low failure, high efficiency and stability.

5. Built in process design of nose beam strip, greatly reducing subsequent processing procedures.

3、Equipment parameters

1. Equipment size:

(1)3300*1780*1020

(2)1000*500*1220

(3)930*550*1500

2.Equipment color: silver+profile

3.Voltage:380V,50Hz

Email

Email